UPF 50+ Explained: The 2026 Ultimate Guide to UV Protection Standards for B2B Buyers

Introduction

In the global activewear and outdoor market, “Sun Protection” is no longer a “nice-to-have” feature—it is a critical compliance requirement. As we move into the 2026 sourcing season, the demand for high-performance UV-protective apparel is being driven by educated consumers and stricter health regulations, particularly in regions like Australia and the EU.

For brands, importers, and sourcing managers, the challenge is not just finding a fabric that claims “UPF 50+”; it is understanding the science and legality behind that claim. A fabric that passes US standards might fail in Australia. A coating that works on day one might wash off by day thirty.

As a technical authority in performance textiles, IgerEnjoy has prepared this cornerstone guide to demystify UPF standards. We will move beyond the marketing fluff to examine the physics of UV blocking, the specific testing protocols of global markets, and how to source fabrics that protect both your customers’ skin and your brand’s reputation.

1. What is UPF 50+? (The Technical Definition)

Before discussing procurement, we must define the metric.

UPF (Ultraviolet Protection Factor) indicates how much UV radiation (both UVA and UVB) a fabric allows to reach the skin. It is the textile equivalent of SPF (Sun Protection Factor), which is used for liquids/lotions.

The Math: A UPF rating of 50 allows only 1/50th (or 2%) of UV radiation to pass through. It blocks 98% of UV rays.

The Rating System:

UPF 15-24: Good Protection.

UPF 25-39: Very Good Protection.

UPF 40-50+: Excellent Protection.

Critical Distinction: SPF measures time (how long you can stay in the sun without burning). UPF measures transmission (how much radiation penetrates the barrier). For B2B buyers, UPF is the only metric that matters for textiles.

2. Why “Compliance” is Your Biggest Risk

In 2025/2026, regulatory scrutiny is tightening. Labeling a garment “Sun Protective” classifies it as PPE (Personal Protective Equipment) in the European Union (Regulation EU 2016/425).

If your product claims UPF 50+ but fails to meet the specific testing standard of the destination country, you face:

Customs Seizures: Goods blocked at the border.

Mandatory Recalls: Costing millions in reverse logistics.

Liability Lawsuits: If a consumer suffers sun damage despite your claims.

At IgerEnjoy, we ensure every yard of fabric is tested according to the specific destination market’s protocol.

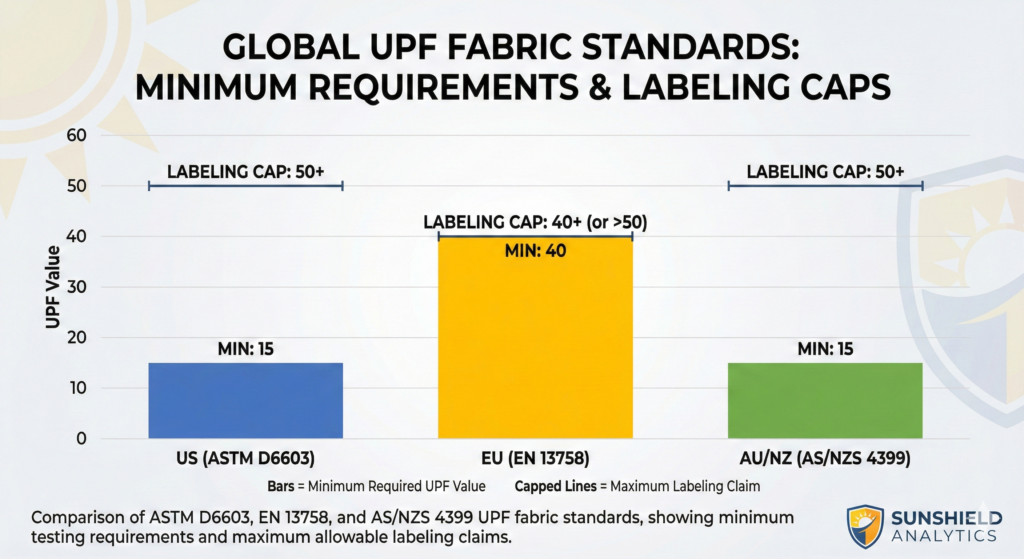

3. Global Standards Compared: ASTM vs. EN vs. AS/NZS

This is the most confusing aspect for buyers. A UPF 50 result in the USA does not automatically equal a UPF 50 result in Australia.

The following comparison table highlights the critical differences between the three major regulatory bodies:

| Feature | USA Standard | EU Standard | AU/NZ Standard |

| Test Method | AATCC 183 | EN 13758-1 | AS/NZS 4399:2017 |

| Labeling Standard | ASTM D6603 | EN 13758-2 | AS/NZS 4399 |

| Solar Spectrum | Albuquerque, NM (High Intensity) | Albuquerque, NM (High Intensity) | Melbourne, AU (Highest Intensity) |

| Body Coverage | No specific requirement. | Requires max skin coverage (long sleeves/legs) to claim protection. | Requires specific body coverage designs to carry the label. |

| Labeling Cap | UPF 50+ | UPF 40+ (Conservative) | UPF 50+ |

| Minimum Rating | UPF 15 | UPF 40 (Very Strict) | UPF 15 |

| Durability | Recommended (ASTM D6544) | Mandatory for PPE claims | Not strictly mandatory in the standard, but expected by retailers. |

The “Dry vs. Wet” Trap

Most standard tests (AATCC 183) test the fabric dry and unstretched. However, when a consumer swims or hikes, the fabric gets wet and stretches. Water reduces the scattering of light, and stretching opens the pores, drastically reducing UPF.

IgerEnjoy’s Approach: For our premium swimwear and activewear clients, we recommend the UV Standard 801 (a private EU standard). It tests fabrics wet, stretched, and abraded. It is the “Gold Standard” for honesty in marketing.

4. The Material Science: How We Engineer UPF 50+

Many sourcing managers believe UPF is just a chemical coating. While coatings exist, they wash out. IgerEnjoy focuses on “Inherent Protection”—engineering the defense into the DNA of the fabric.

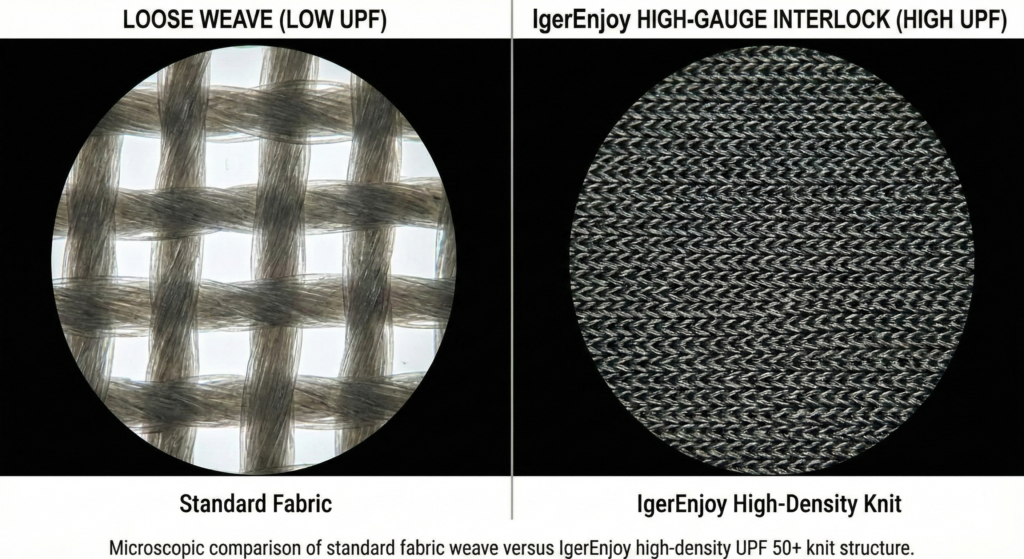

A. Fiber Composition & Density (The Physics)

The first line of defense is the physical barrier.

Cover Factor: We utilize high-gauge circular knitting machines (28G to 44G) to create an ultra-tight weave. If visible light cannot pass through, UV rays likely cannot either.

Fiber Type: Polyester (PET) and Nylon naturally absorb more UV radiation than Cotton or Viscose due to their benzene ring molecular structure.

B. Ceramic Additives (Full Dull Yarn)

To achieve UPF 50+ in lightweight summer fabrics (GSM < 130), we use “Full Dull” yarns.

Mechanism: During the spinning process, we embed nano-scale Titanium Dioxide (TiO2) or Zinc Oxide particles into the polymer melt.

Benefit: These ceramic particles act as millions of tiny mirrors, reflecting UV rays away from the body. Because they are inside the yarn, they never wash out. This is the IgerEnjoy standard for durability.

C. Color Theory

Dark Colors: Black and Navy naturally absorb UV.

Light Colors: Achieving UPF 50+ in White or Pastel fabrics is the ultimate technical challenge. IgerEnjoy solves this by using specialized Optical Brightening Agents (OBAs) that absorb invisible UV light and re-emit it as visible blue light, effectively blocking the harmful rays while making the white look brighter.

5. 2026 Trends: What Buyers Are Asking For

Based on market data from WGSN and recent search trends, here is what will define the 2026 sun-protection market:

Trend 1: “Weightless” Protection

Consumers want high protection without the heat. The demand is for Ultra-Lightweight (80-100 GSM) fabrics that still pass UPF 50+.

IgerEnjoy Solution: We have developed a micro-denier interlocking structure that maintains high opacity and UV blocking at incredibly low weights, perfect for trail running and fishing shirts.

Trend 2: Chemical-Free & Sustainable

The “Clean Beauty” movement has migrated to textiles. Buyers are rejecting heavy chemical UV dips.

IgerEnjoy Solution: Our Recycled UPF Collection uses GRS-certified Recycled Polyester (rPET) with physical TiO2 blocking agents. No formaldehyde, no heavy metals, and no temporary chemical baths.

Trend 3: Hybrid Functionality

UPF is no longer a standalone feature. It must be paired with:

Cooling: Jade-powder infused yarns.

Wicking: Cross-section moisture management.

Anti-Odor: Silver ion treatments.

6. Sourcing Checklist: How to Verify Your Supplier

Don’t rely on a simple “Yes” from a salesperson. Use this checklist when sourcing UPF fabrics:

Ask for the Report Date: Is the test report less than 12 months old?

Check the Wavelength: Does the report cover both UVA (aging) and UVB (burning)?

Pre-Treatment Verification: Ask, “Was this tested after laundering?”

Professional Tip: Request testing after 40 wash cycles (AATCC 135) and simulated sunlight exposure (ASTM D6544). This proves the quality of the IgerEnjoy fabric to your end consumer.

Match the Standard to the Region: Do not send an AATCC 183 report to an Australian retailer; they will likely reject it.

Conclusion

In the B2B textile industry, UPF 50+ is a promise of safety. It requires a synergy of high-density knitting, advanced polymer science, and rigorous third-party testing.

As brands face stricter regulations and higher consumer expectations in 2026, partnering with a supplier who understands the nuance of global standards is essential. At IgerEnjoy, we don’t just sell fabric; we provide the technical data and certification backing you need to enter any market with confidence.

Ready to secure your 2026 collection?

Contact IgerEnjoy today to request our “High-Protection Lab Series” sample book, complete with SGS test reports for US, EU, and AU markets.

FAQ

Question: What is the difference between UPF 50 and UPF 50+?

Answer: UPF 50 allows 1/50th (2%) of UV radiation to pass through. UPF 50+ is the highest possible rating in most international standards (ASTM, AS/NZS), indicating the fabric blocks more than 98% of UVA and UVB rays. It offers the maximum level of protection available in apparel.

Question: Does UPF protection wash out of the fabric?

Answer: It depends on the manufacturing method. If the fabric relies solely on a chemical finish (dip coating), the protection will diminish after 10-20 washes. If the fabric uses “inherent” protection (like IgerEnjoy’s TiO2 infused yarns or tight weave structure), the UPF rating is permanent and will last the life of the garment.

Question: Can white or light-colored fabrics be UPF 50+?

Answer: Yes, but it requires advanced engineering. While dark colors naturally absorb UV, light colors need high-density knitting and the addition of specific UV-absorbing additives (like ceramic particles or optical brighteners) to achieve a UPF 50+ rating. Always check the test report for light colors specifically