Crafting Process of Outdoor Beach Umbrellas

| Expert Manufacturer - igerenjoy

Discover the manufacturing process of outdoor beach umbrellas by igerenjoy: from 2D printing drafts to exquisite stitching. With thirteen years of experience and BSCI, ISO certification, we provide high-quality umbrellas worldwide. Elevate your outdoor experience with stylish and comfortable umbrellas.

Amidst the delightful moments of outdoor leisure, beach umbrellas stand as symbols of comfort and relaxation. With over thirteen years of manufacturing experience and backed by certifications such as BSCI and ISO, we are committed to providing high-quality outdoor beach umbrellas for consumers worldwide. Our dedication to focus, innovation, and impeccable craftsmanship has earned us trust and reputation in the industry.

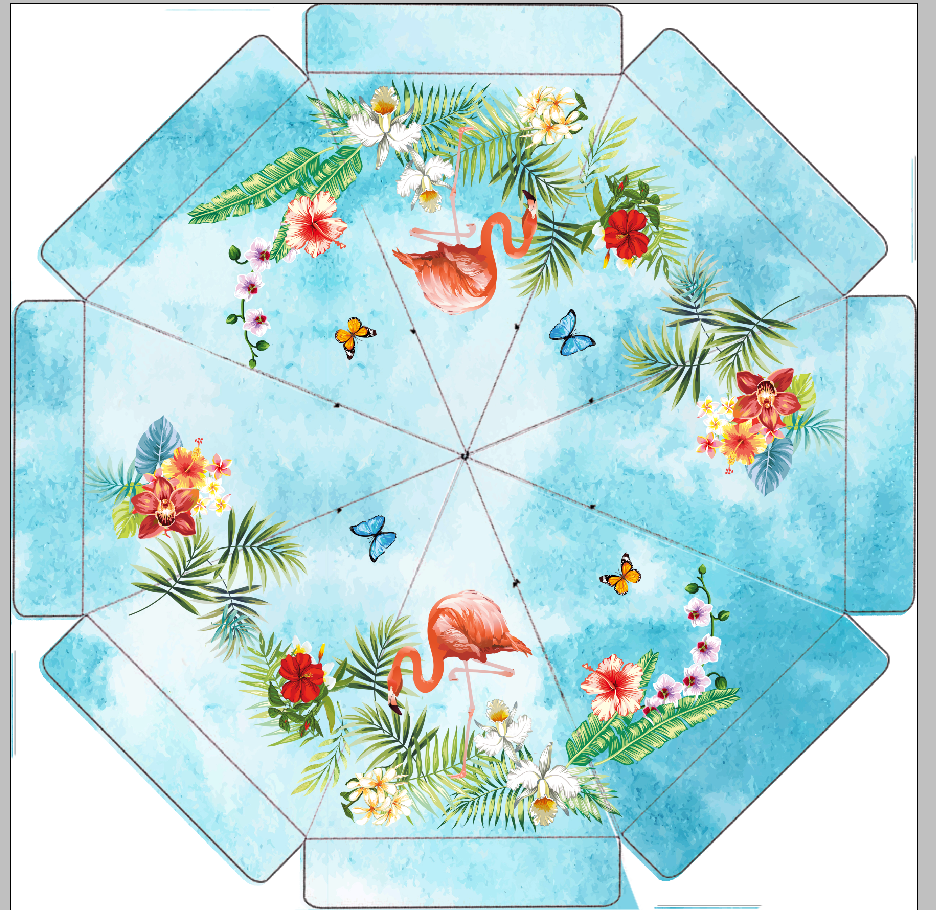

1. 2D Printing and Drafting: The production process begins with the creation of 2D drafts. Meticulously crafted design patterns and logos are applied to the umbrella fabric, ensuring not only uniqueness in quality but also visual appeal.

2. Printing (Digital, Screen, Heat Transfer): Based on the 2D drafts, we choose the most suitable printing technique, such as digital printing, screen printing, or heat transfer. These methods ensure that the design is precisely transferred onto the umbrella fabric, guaranteeing vibrant and long-lasting colors.

3. Fabric Cutting According to Umbrella Shape: The printed fabric is then precisely cut according to the shape of the umbrella. We ensure that each piece of fabric is tailored to fit the exact dimensions of the umbrella shape, establishing a solid foundation for the subsequent manufacturing stages.

4. Sewing Fabric Pieces to Create Canopy: The cut fabric pieces are sent to the sewing workshop. There, skilled artisans employ their sewing expertise to meticulously stitch the fabric pieces together, crafting a remarkable umbrella canopy.

5. Assembling the Frame: Simultaneously, the production of metal poles and connectors is underway. Once the canopy and frame are ready, they are expertly assembled to ensure the stability and integrity of the umbrella frame.

6. Stitching the Complete Umbrella: The combined canopy and frame are meticulously sewn together using sophisticated sewing techniques. This ensures a snug fit of the canopy to the frame, allowing the beach umbrella to be smoothly unfolded and folded at various angles.

7. Quality Inspection and Packaging: Quality remains our utmost priority. At every stage of production, rigorous quality checks are performed. After the complete umbrella is manufactured, our quality inspection team thoroughly examines every detail, ensuring print quality, stitching durability, and overall performance. Upon passing inspection, products are carefully packaged to ensure safety during transportation.

8. Shipping: With stringent quality checks and meticulous packaging, our ready-to-use outdoor beach umbrellas are shipped to global sales channels. Consumers can purchase them from retail stores, online shops, and wholesale distributors, adding a touch of style and comfort to their outdoor experiences.

With over thirteen years of manufacturing experience and supported by certifications such as BSCI and ISO, “igerenjoy” is dedicated to providing high-quality outdoor beach umbrellas. Combining design creativity with exquisite craftsmanship, we infuse each product with unique quality and style, enhancing outdoor leisure moments with comfort and unforgettable charm.