Fiberglass vs Steel Beach Umbrella:

Which is Best for Your Business?

Every B2B procurement officer faces the same dilemma before the summer season. You are looking at two quotes for a beach umbrella. One specifies “Steel Ribs” and is cheaper. The other specifies “Fiberglass Ribs” and costs 15-20% more.

Is the upgrade worth it?

When analyzing a Fiberglass vs Steel Beach Umbrella, you aren’t just comparing metals and polymers; you are comparing two completely different business models. One focuses on low entry cost, while the other focuses on brand reputation and longevity.

As a source factory (IgerEnjoy/Nissi Tech) with 15 years of experience manufacturing both, we are here to give you the transparent, technical truth to help you decide.

1. The Core Engineering Difference

To understand the performance, we must first look at the material science.

Steel Ribs: The Rigid Traditionalist

Steel ribs are typically made from carbon steel wire or hollow tubes. In the beach umbrella industry, they rely on rigidity to hold the canopy shape.

Structure: Usually 8 ribs, varying from 2.8mm to 4.0mm in thickness.

Treatment: Must be powder-coated or zinc-plated to prevent oxidation.

Behavior: When wind hits, steel resists. It fights the wind until it reaches its “Yield Point.” Once that point is crossed, the metal bends permanently.

Fiberglass Ribs: The Flexible Modernist

Fiberglass (FRP – Fiber Reinforced Polymer) ribs are solid rods made of glass fibers embedded in a resin matrix.

Structure: Solid rods, typically 5.0mm to 6.0mm thick for commercial grade.

Treatment: Naturally corrosion-resistant; often colored black or white during the extrusion process.

Behavior: When wind hits, fiberglass flexes. It absorbs the energy by bending and then springs back to its original shape (Memory Effect).

2. Detailed Performance Comparison

Let’s dive deeper into the three metrics that matter most to your end-users.

Round 1: Wind Resistance (The “Gust” Test)

The Scenario: A sudden 30 mph (48 km/h) gust of wind hits the beach.

Steel’s Reaction: The rigid steel frame takes the full force of the wind load. If the umbrella is not vented properly, the pressure builds up on the ribs. Often, the ribs will buckle (invert) or the hollow steel tube will snap at the rivet point.

Result: The umbrella is trash. A bent steel rib cannot be bent back without weakening it further.

Fiberglass’s Reaction: The fiberglass ribs bend with the wind, sometimes turning the umbrella slightly inside out without damage, or simply flattening out to let the wind pass. As soon as the gust passes, they snap back to the correct shape.

Result: The user simply resets the umbrella, and it works perfectly.

Winner: Fiberglass. It is structurally superior for coastal environments.

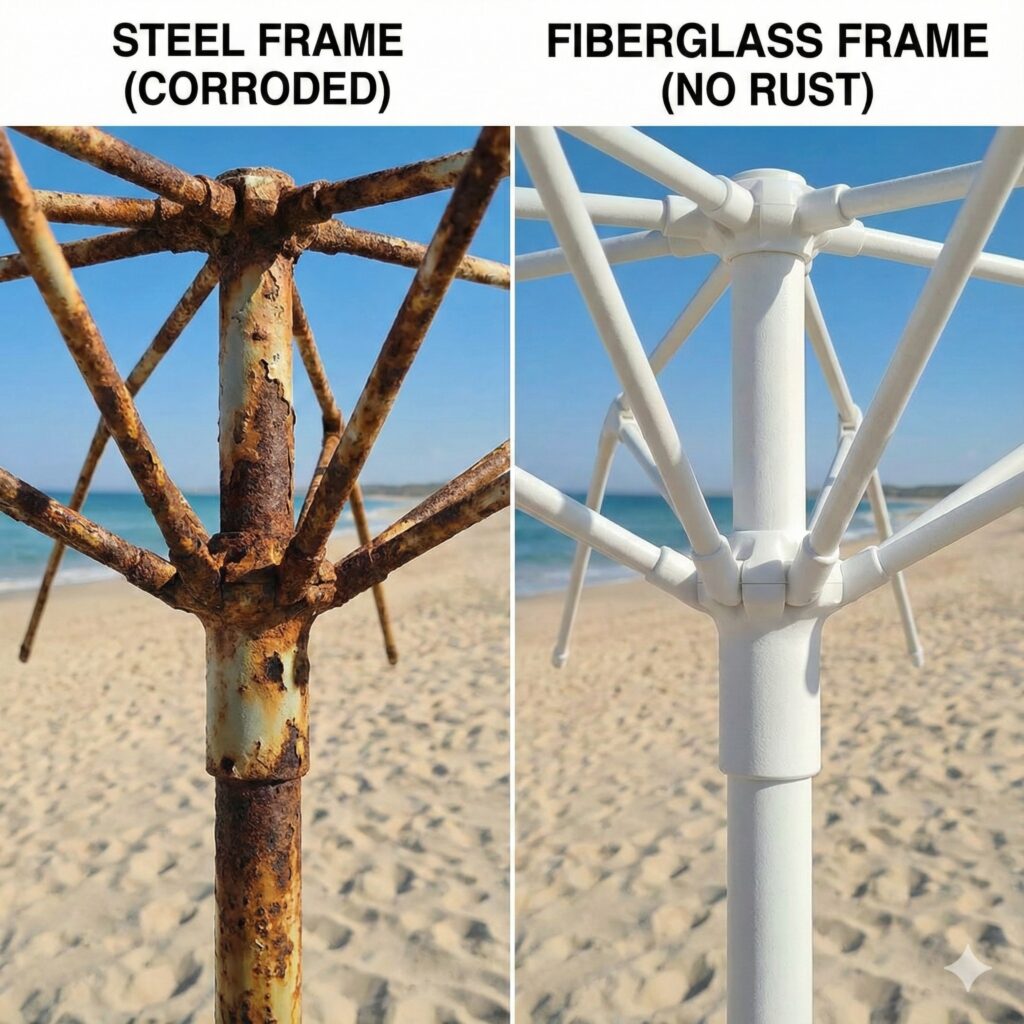

Round 2: Corrosion & Rust (The “Salt” Test)

The Scenario: The umbrella is used daily at a seaside resort, exposed to high humidity and salty air.

Steel’s Reaction: Even the best powder coating has microscopic pores. Over time, or if the ribs scratch against each other during transport, the salt air penetrates. You will see “orange bleeding” (rust stains) on the white fabric canopy within 1-3 months in humid climates.

Fiberglass’s Reaction: Fiberglass is a non-metallic composite. It is chemically inert to salt oxidation. It simply cannot rust.

Factory Note: At IgerEnjoy, we use fiberglass ribs that can pass a 1,000-hour Salt Spray Test, whereas standard steel ribs often fail after 48-72 hours.

Winner: Fiberglass. Essential for any beach-front property.

Round 3: Aesthetic & Weight

Steel: Heavier. This can be seen as a “quality” feel by some older consumers, but it makes carrying the umbrella difficult. The ribs look thin and wire-like.

Fiberglass: Lighter but stronger. The ribs are thicker (5mm+), giving a robust, premium look to the underside of the umbrella.

Winner: Tie. (Depends on customer preference).

3. The “Hidden Cost” Analysis (ROI)

For B2B buyers, price is always a factor. Let’s look at the math of Fiberglass vs Steel Beach Umbrella procurement over 2 years.

Option A: The Budget Steel Umbrella

Unit Cost: $5.00

Lifespan: 3-6 Months (One Season)

Replacement Rate: 100% per year due to rust or wind damage.

Total Cost over 2 Years: $5.00 (Year 1) + $5.00 (Year 2) = $10.00 + Logistics costs for 2 shipments.

Option B: The Premium Fiberglass Umbrella

Unit Cost: $6.50

Lifespan: 24+ Months (Multiple Seasons)

Replacement Rate: <10% (Lost or stolen, rarely broken).

Total Cost over 2 Years: $6.50.

Conclusion: While Steel is cheaper upfront, Fiberglass is 35% cheaper over a 2-year cycle. This is a powerful selling point you can use with your retail or commercial clients.

4. Manufacturing Quality: What to Ask Your Supplier

Not all fiberglass is created equal. When sourcing, ask these questions to ensure you aren’t buying “fake” or low-quality fiberglass.

“Is it Solid or Hollow?”

Always insist on Solid fiberglass ribs (5.0mm or 6.0mm). Some factories use hollow fiberglass tubes to save money, but these split easily under pressure.

“What is the Joint Material?”

The point where the rib meets the hub (runner) is critical. At IgerEnjoy, we use reinforced high-impact plastic caps or stainless steel rivets. Cheap suppliers use thin aluminum wire that corrodes and breaks the fiberglass connection.

“Do you have an ASTM B117 Report?”

If you must buy Steel, demand a Salt Spray Test report. If they cannot provide one, assume the ribs will rust in 2 weeks.

5. Summary Table: Quick Selection Guide

| Feature | Standard Steel Ribs | IgerEnjoy Fiberglass Ribs |

| Material | Carbon Steel Wire/Tube | Solid FRP (Fiber Reinforced Polymer) |

| Wind Rating | Low (Static) | High (Dynamic Flex) |

| Rust Proof? | No (Coating dependent) | Yes (100%) |

| Recyclability | High (Metal scrap) | Low (Composite waste) |

| Ideal for… | Giveaways, Promotions | Resorts, Rentals, Retail Brands |

Conclusion

The verdict on the Fiberglass vs Steel Beach Umbrella debate is clear for 2026 sourcing.

If you are running a promotional campaign (e.g., a beer brand giving away 10,000 umbrellas for a one-day event), Steel is the correct economic choice. It looks good enough and hits the low price point.

However, if you are a Retail Brand, Hotel Supplier, or E-commerce Seller (Amazon/Shopify) looking for 5-star reviews and repeat customers, Fiberglass is the only viable option. The slight increase in unit cost pays for itself by eliminating warranty claims and rust complaints.

Ready to see the difference?

At IgerEnjoy, we specialize in helping brands upgrade from Steel to Fiberglass without breaking the budget. Contact us today to request a sample of our 5.0mm Wind-Flex Fiberglass frame

FAQ Schema Content:

Q: What is the main difference in a Fiberglass vs Steel Beach Umbrella?

A: The main difference is durability. Fiberglass ribs are flexible and can bend in the wind without breaking, whereas steel ribs are rigid and prone to bending permanently or snapping. Fiberglass is also rust-proof.

Q: Is a fiberglass umbrella worth the extra cost?

A: Yes, for commercial or retail use. Although fiberglass costs about 15-20% more upfront, it lasts 2-3 times longer than steel because it doesn’t rust or break in the wind, offering a better ROI.

Q: Can steel beach umbrellas be rust-proof?

A: Not entirely. While zinc plating and powder coating delay rust, the harsh friction of opening and closing the umbrella eventually scratches the coating, leading to rust. Fiberglass is the only truly rust-proof option